Tektoniks

Modern construction requires a modern building solution, and Tektoniks is Bensonwood’s way to bring our state-of-the-art system of offsite, panelized construction to nearly any wood-based project. We partner with Architects, Builders and Homeowners to offer energy-efficient building solutions to their custom Residential, Multifamily, Commercial, and Institutional designs. It combines the efficiency of high performance building envelopes with the structural flexibility of mass timber, enabling projects to reach Passive House, Net Zero, and USGBC LEED Certification.

Platform Benefits

- Direct access to Bensonwood fabrication capabilities

- High performance enclosures for custom-designed projects

- Standard insulated panel building system

- Factory-level precision

- Factory-installed windows and doors

- Protection from the weather and mold

- Passive-house level airtightness typically at .6 ACH/-50 pascals

- Durable, long lasting materials

- Decarbonization through sustainable materials

- A solution when local skilled labor is unavailable

- Predictable timelines and fixed costs

- Shared library of pre-engineered components

- Repeatable design details and dimensional standards

- Design and engineering support throughout the process

- Early pricing and scheduling to guide decisions

What Can You Build With Tektoniks?

Multi-Family & Commercial

Panelized high performance building envelopes for duplex, townhouse and small apartment and other Commercial buildings.

Institutional

Passive House-level performance for Institutions building with future generations in mind.

Mass Timber

Glulaminated and Cross-laminated Timber solutions for small to mid-scale Institutional and Commercial projects.

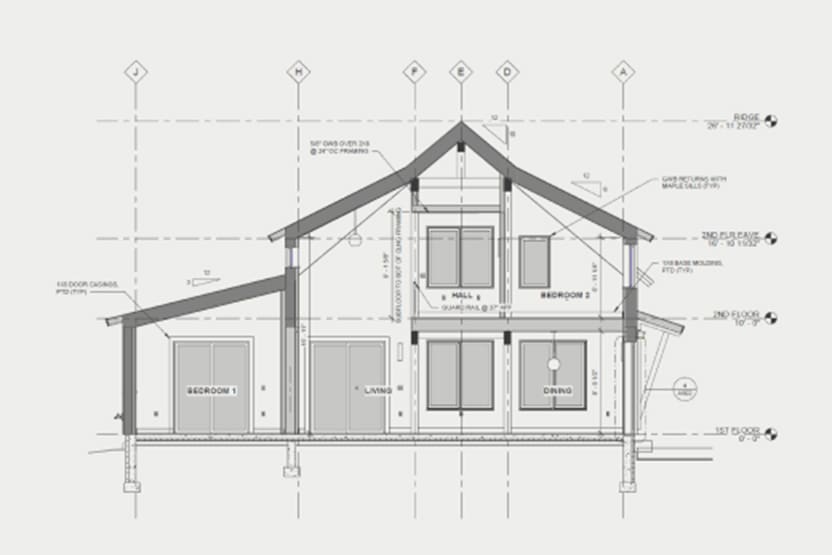

Timber Frame

Homes and buildings that celebrate historic timber framing produced with cutting-edge technique.

Architectural Millwork

Exceptionally fine stairs, interior doors, entrances, and trim packages to complete the job.

-

The Common Ground School, designed by Gray Organschi Architects, incorporates CLT panels and glulam beams for the structure. The building is certified LEED Gold and Net Zero ready.

The Common Ground School, designed by Gray Organschi Architects, incorporates CLT panels and glulam beams for the structure. The building is certified LEED Gold and Net Zero ready. -

Designed by Aamodt/Plumb Architects, who turned to Bensonwood for our expertise in the off-site manufacturing of prefabricated building components.

Designed by Aamodt/Plumb Architects, who turned to Bensonwood for our expertise in the off-site manufacturing of prefabricated building components. -

The Catskill Project from partner Buck Moorhead is a carbon-neutral community in Livingston Manor, NY and each model utilizes Bensonwood's OpenBuilt enclosure system and structural timbers.

The Catskill Project from partner Buck Moorhead is a carbon-neutral community in Livingston Manor, NY and each model utilizes Bensonwood's OpenBuilt enclosure system and structural timbers. -

The Bosarge Family Education Center at the Coastal Maine Botanical Gardens was designed in collaboration with Maclay Architects and Scott Simons Architects using OpenBuilt enclosure system and CLT structure.

The Bosarge Family Education Center at the Coastal Maine Botanical Gardens was designed in collaboration with Maclay Architects and Scott Simons Architects using OpenBuilt enclosure system and CLT structure. -

Designed by Bruner/Cott & Associates to be Net Zero and meet the rigorous requirements of the Living Building Challenge, the R.W. Kern Center at Hampshire College demonstrates Hampshire College's commitment to a sustainable future.

Designed by Bruner/Cott & Associates to be Net Zero and meet the rigorous requirements of the Living Building Challenge, the R.W. Kern Center at Hampshire College demonstrates Hampshire College's commitment to a sustainable future.

The Tektoniks Process

Design and Build with Tektoniks

Tektoniks is a viable solution for architects and builders who share our commitment to cleaner, healthier construction and fighting climate change.

We look forward to collaborating with like-minded architects and builders who are ready to apply their creative ideas to our standards-based system of building. Let’s see what we can do together.