Where High Performance and Comfort Meet

Passive House Principles

- High quality insulation

- Thermal bridge-free design

- Airtight construction

- Heat control and robust windows

- Heat recovery ventilation

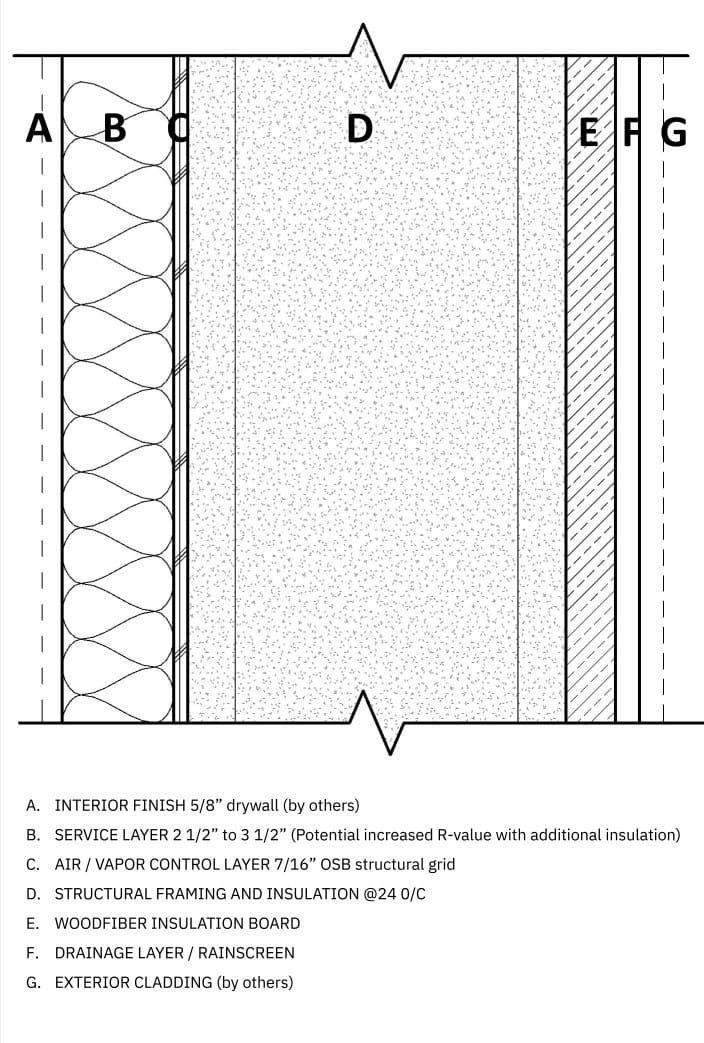

The Building Enclosure

Air and Moisture Management

Our walls manage moisture by utilizing the smart vapor permeance benefits of Oriented Strand Board and the hygroscopic properties of cellulose. A semi-vapor open assembly allows for drying in both directions, making it ideal for all climates, and balanced, continuous mechanical ventilation manages interior humidity reducing the amount of moisture that enters the assembly.

High-performance tapes and specialized gaskets are used to seal the panel joints ensuring that no water or air enters our panels. These systems provide immediate protection and long-term airtight performance.

All materials in our homes are evaluated carefully relative to their impact on indoor air quality to avoid unhealthy substances and off-gassing.

Windows and Doors

We specify and source super-efficient triple-paned, tightly sealed, and insulated windows to satisfy stringent Passive House thermal and airtightness requirements. Our designs consider the amount of glazing and its orientation in the building to optimize thermal performance and comfort.

In addition, we design and build wooden exterior doors that are 3 ¼” thick featuring a rigid insulation core and a double-rabbeted (stepped) jamb with two layers of weatherstripping. We install a 3-point locking mechanism that draws the door tight to the weatherstripping providing an airtight seal.

See our Architectural Millwork page for more information about our doors. Architectural Millwork – Bensonwood Custom Homes

How We Build

- Design and engineer buildings that matter – with support throughout the process

- Virtual Build with computer aided design – all models begin with 3D models and undergo a verification process for accuracy

- Fabrication – our Building Systems team makes precision milled and super-insulated components that are assembled in a controlled factory environment

- Factory Installation – we install hardware, exterior doors, and windows in the wall systems eliminating costly mistakes and saving time at the construction site

- Transport – our logistics and building teams expertly bundle and wrap the building elements so they arrive safely at the construction site

- Site Assembly – building components are efficiently assembled by a qualified team at the construction site with minimal waste of materials

Passive House Certification

PHIUS (Passive House Institute US) and PHI (Passive House Institute Germany) are Passive House accredited certification bodies. They educate and guide the design and construction of passive building structures. Our Certified Phius Builder professionals are committed to helping you achieve your energy and wellness goals.

If you are seeking Passive House certification, we can work with your partners – architects, general contractors and developers to help meet your objectives.

Let's Discuss Your Building Objectives

Meet Our Passive House Team:

Hans Porschitz

Hans leads daily operations at Bensonwood and oversees the company’s research and development of improved systems and products for the construction industry. As a member and coordinator of the collaborative “Open-Prototype Initiative,” he participated in a number of innovative projects including the Net Zero, LEED Platinum, Unity House, and BrightBuilt Barn, as well as the renowned Loblolly house.

Jay Lepple

Jay leads operations of the building systems manufacturing facility in Keene that produces wall, floor and roof enclosures for Bensonwood and Unity Homes. He serves as an instructor for partner builder classes at Bensonwood, and was a presenter at the 2016 Passive House conference and collaborated with the television series, This Old House, on the Bensonwood Weston house in 2006.