Our Mission + Values

"With peoples’ lives as our focus, there’s no such thing as ‘good enough;’ there’s always something we can improve."

A New England Tradition

Our History

Our Team

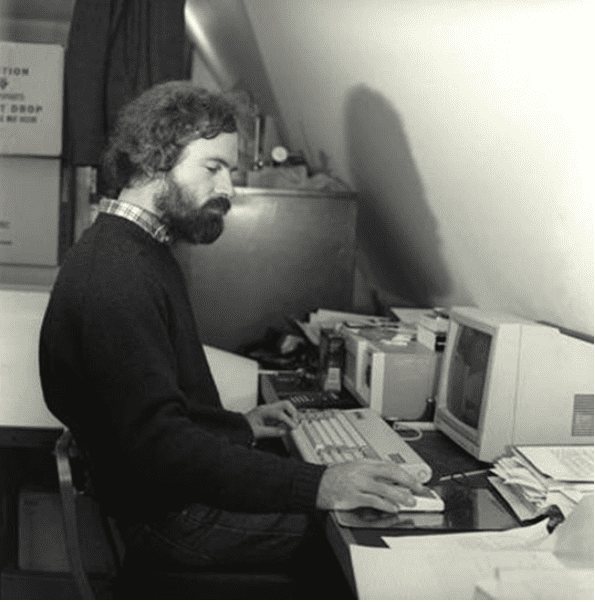

Tedd Benson

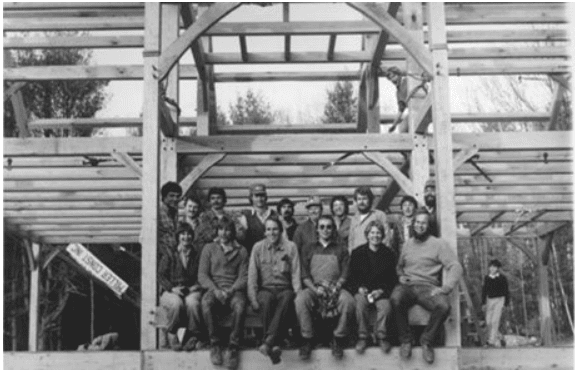

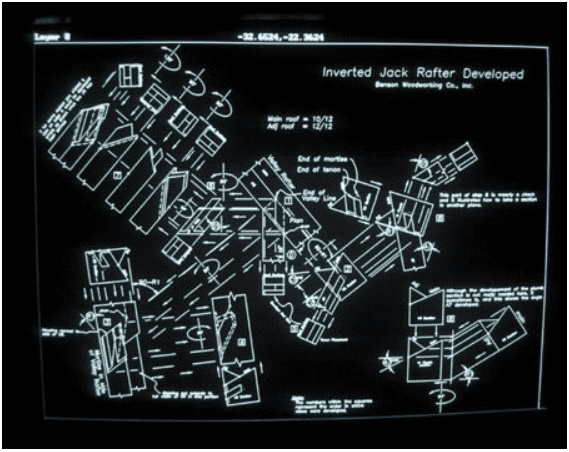

Author, Building Pioneer, Founder, and CEO of Bensonwood & Unity Homes Tedd, founder of Bensonwood (1973) and Unity Homes (2012), has devoted his life to developing a better way to build. Realizing in his youth the undeniable benefits of timber construction, Tedd was a crucial figure in the revival of timber framing in America. He was one of the founders of the Timber Framers Guild of North America (1984) and authored four books on the subject. Through the following decades, Bensonwood established itself as a creative leader in timber frame design, engineering, craftsmanship, and CAD‐CAM technology. This work has taken the company to nearly every state in the U.S. (Oklahoma is a holdout), as well as Canada, England, and Japan.

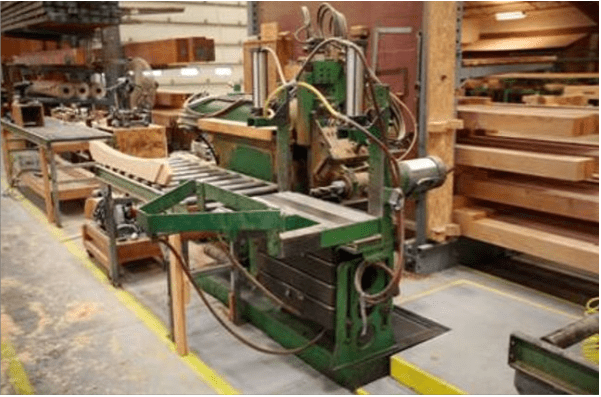

Today, Bensonwood continues that forward thinking and leadership, not only pioneering the use of Mass Timber and CLT’s in buildings large and small but also turning their focus towards the development of new systems, processes, logistics and technology that focus on making high performance and sustainable homes the industry norm. To that end, Tedd went on to found Unity Homes, a brand of Bensonwood, and recently developed a state of the art manufacturing facility in Keene, NH. This facility is one of only a few of its kind in the entire country. Tedd is a nationally known speaker and presenter and is the recipient of many awards, including an honorary doctorate from Unity College, and most recently, The Granite State Award in recognition of his statewide and national influence on best building practices.

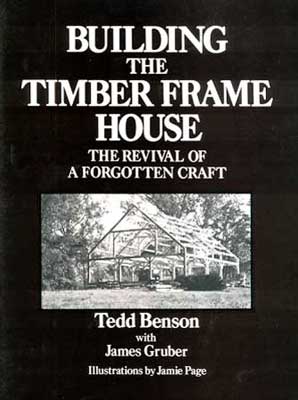

Books by Ted Benson:

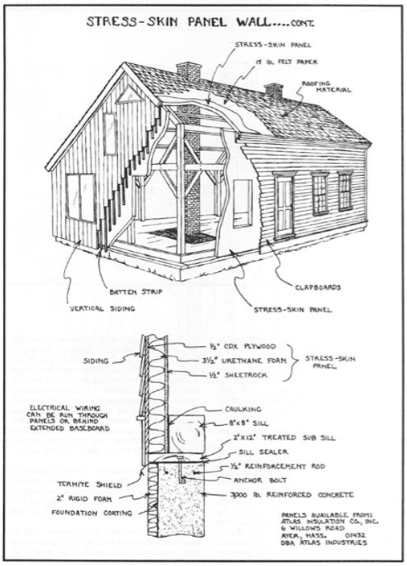

Whereas Tedd’s first book focused on how to cut and assemble timber frames, his second book was about all the other steps required to design and build a timber frame home. Based on the experience of having built hundreds of timber frame homes throughout New England and beyond, this book provided a logical and necessary complement to Tedd’s first book, and was an indispensable handbook for anyone contemplating a timber frame home.

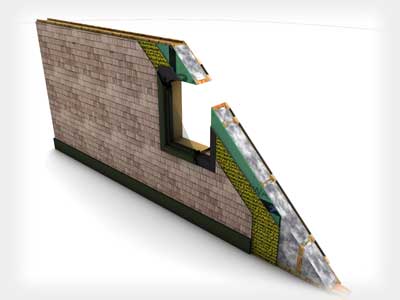

As the timber frame revival gathered momentum, the materials and methods for building these homes evolved rapidly. Unity’s parent company Bensonwood was at the forefront of a flurry of innovation that improved the design, engineering, fabrication and construction of timber frame homes. In his third book, Tedd describes the state-of-the-art of building timber frame homes at the turn of the last century, with Bensonwood having played a key role in many of the most important developments.

Foreword by Norm Abram (former host of PBS’s This Old House and New Yankee Workshop)

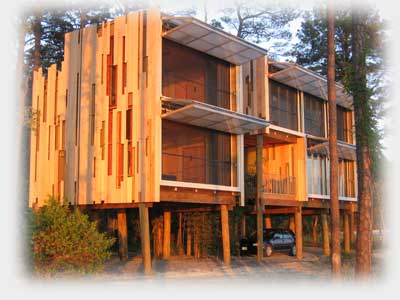

Tedd’s fourth book celebrates the beauty and craftsmanship of timber frame homes. This coffee table tome includes case studies and gorgeous photographs of 29 homes built in a variety of styles across the country. Most of the homes were designed and built by Bensonwood, but the book also includes examples of work by other celebrated timber frame home companies. The book remains one of the most inspirational timber frame design books ever to be published.